4,000 square feet

Tallahassee, Florida

Oldcastle Coastal

Zephyrhills, FL

Jon Huyck, PE

ANCHOR DIAMOND

Randy L. Friloux

Associated Construction Products, Inc.

Lutz, FL

Project Management

Kevin Heuerk

Anderson Columbia

Monticello, FL

4,000 square feet

Tallahassee, Florida

Oldcastle Coastal

Zephyrhills, FL

Jon Huyck, PE

ANCHOR DIAMOND

Randy L. Friloux

Associated Construction Products, Inc.

Lutz, FL

Project Management

Kevin Heuerk

Anderson Columbia

Monticello, FL

The aging Orange Avenue trestle bridge crossing the historic St. Marks Trail in Tallahassee, FL, needed to be replaced. With a pedestrian/bike trail crossing diagonally beneath the bridge, the excavation area for the bridge support walls was limited. Timing was critical as this busy road serves an elementary school and would have to be replaced during summer break. Limited funds also needed to be taken into consideration for determining the best way to replace the bridge.

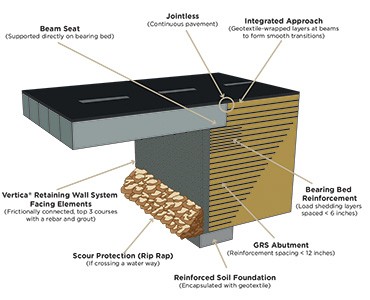

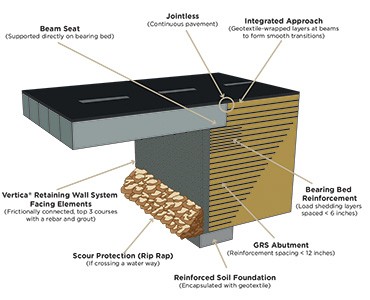

A Geosynthetic Reinforced Soil-Integrated Bridge System (GRS-IBS) was determined by the Florida Department of Transportation (FDOT) to be the best system for small bridge projects with limited time and funds. GRS-IBS technology uses alternating layers of compacted granular fill materials and geotextile reinforcement to provide support for the bridge. Selecting the Anchor™ Vertica® retaining wall product with a near-vertical batter helped address excavation limitation as well as ensure a widened pass-through for the trail.

GRS-IBS is currently limited to single span bridges less than 140 feet in length and abutment heights up to 30 feet with a maximum superstructure bearing pressure of 4000 psf. GRS-IBS systems generally require only common equipment and materials. Construction time and costs are reduced (generally 25 to 60 percent) compared to conventional bridge construction methods and the flexible design can easily be modified in the field for unforeseen site and weather conditions.

When school was out for the summer, the road closed and the project commenced. The old trestle bridge was demolished and excavation began for the bridge support walls. The 18-foot GRS abutment walls had acute angles that required special cuts in the Vertica block, which were reinforced with rebar at the corner, and on either side. The block cores were then filled with grout for the entire height of the abutment to prevent separation of the corner over time.

This was project manager Anderson Columbia’s first GRS-IBS installation. However, the wall contractor, Associated Construction Products, Inc. had experience building several GRS-IBS systems prior to this bridge replacement. Anderson Columbia considered it a positive experience. Because the Vertica block units are dry stacked, the abutment/wing walls went up very quickly to provide support for the superstructure. Additionally, there was no cure time needed in the block wall, which allowed for continuous construction of each abutment and further reduced installation time.

Instead of trying to grade the gravel bridge beam seat to match the shape of the pavement section, a precast concrete beam seat was produced with the bearing surface that match the shape of the pavement section. The precast beams were also ordered prior to commencing the project to ensure they were cured and ready to transport for installation.

The 60-foot-long bridge opened 23 days ahead of schedule, providing significant cost savings to FDOT and allowing plenty of time for the locals to resume their normal commute prior to school opening. A key advantage of the GRS-IBS: a smooth, jointless transition from the bridge onto the roadway alleviating that “bump at the bridge.” And thanks to the nearly vertical bridge support walls, pedestrians and bikers can enjoy a widened underpass.